Why we conduct experimental tests?

Before we convert any formula into a fragrance, we carefully conduct experimental tests not only because it helps in ensuring the client’s satisfaction and in turn, consumers’ satisfaction but it also guarantees the performance of the fragrance.

How stable and unique a fragrance product is going to be, depends on the formula it is made of this is why testing it is a vital part of the manufacturing process.

A fragrance is made up of complex formulas that contain a lot of ingredients. So whenever we develop a new formula, we make sure the ingredients blend perfectly and work together to create an effective and harmonious fragrance just as all the organs of a human body work together to ensure we remain healthy and fit. If one organ doesn’t perform well, the whole body suffers.

Triggers to initiate a test

1. the client requests a test for a product (or multiple)

2. when we develop a new formula about fragrance.

3. regular cyclic testing of old formula that has applied to products.

Test steps

1. Experimental material and source.

First, experimental samples are prepared. These samples come from the following sources:

(1). Samples stored from each batch of products that are already shipped

(2).The high-ranking similar products in the market

(3).Different products containing the same formula

(4).Same products containing a different formula

2. Set the test and reference group.

There would be 3-5 groups usually.

3. Experiment environment control.

The experiment time, space size, temperature, humidity, wind speed, and other factors are formulated based on the using environment of the product.

(1). Home air freshener (plug-in scent, reed diffuser, gel air freshener)

- Space-3m*3m*3m(adjustable)

- Temperature-5℃,20℃ and 40℃(adjustable)

- Wind-≤3.0m/s

- Humidity-30%~65%

(2). Car air freshener (car perfume, car vent air freshener, custom paper freshener)

- Space-1.5m*1m*2m(adjustable)

- Temperature-5℃,20℃ and 40℃(adjustable)

- Wind-≤7.0m/s (simulate the wind speed of the air conditioner)

- Humidity-30%~65%

(3). More complicated environments

4. The formula is tested for:

(1). The strength of the scent

(2). The popularity of the scent

(3). Stability of the formula

(4). Stability of the product structure

5. Evaluation and calculation method.

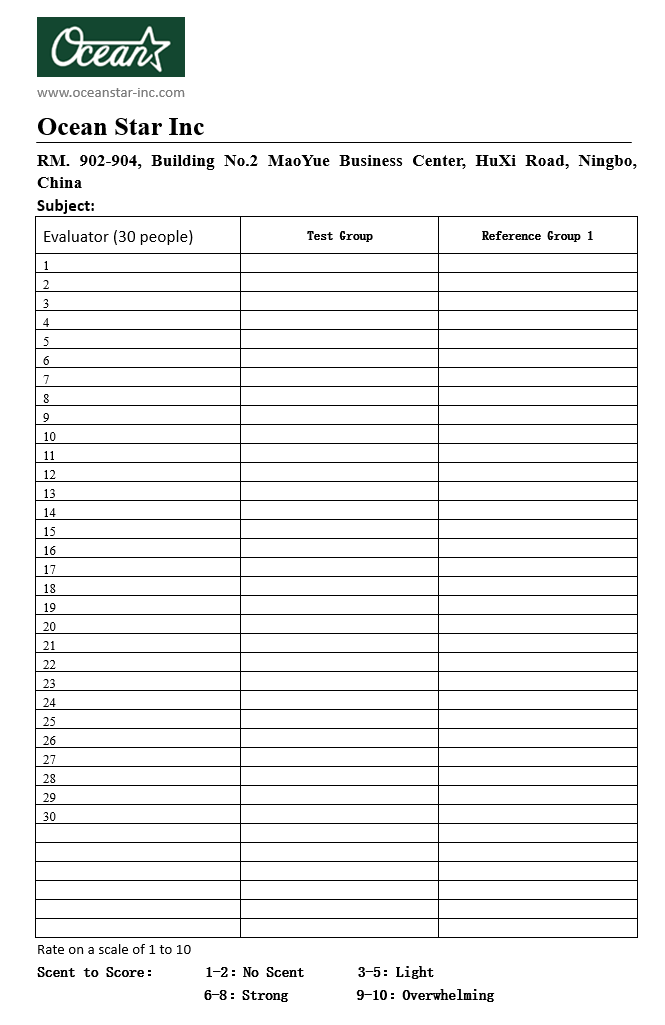

The scent is then rated on a scale of 1 to 10 by thirty people at different points in time. (Monitoring instruments will also be used, but they are more complicated, so I plan not to talk about this here)

6. Data analysis.

After that, we analyze the data obtained from these ratings. Then, we will judge its strength, popularity, stability, etc. according to the fragrance curve of the data.

7. End and more.

If the formula is not according to the required standards, we make necessary changes based on the client’s feedback and our observation by repeating the tests until we get the desired results.